By 1925 it was clear that Longnor needed a proper bridge.

The reinforced concrete, multi-culvert design was innovative at the time.

There had been a number of incidents in the ford at the entrance to Longnor from the main road, particularly when the water was high and fast-flowing, as Ernest Everall recalls:

“With no bridge over the brook, it was quite common for a car to stop in the water and a chain horse had to be got to pull it out. The brook was quite a hazard to horse traffic as well as cars when it was in flood. The story was told of a wagon and two horses which was washed ever so far down the brook. The leading horse – from Bentley Ford – was drowned, but the one in the shafts survived.”

John Bromley of Church Stretton was given the job, and work started in late June 1925. It finished in mid-November. Twenty men worked on the bridge – labourers at 1 shilling per hour and tradesmen at 1 shilling 4d, working 50-hour weeks. The concrete was mixed by hand, and rocks broken by hand. Total cost of the materials = £1,000; labour = £390.

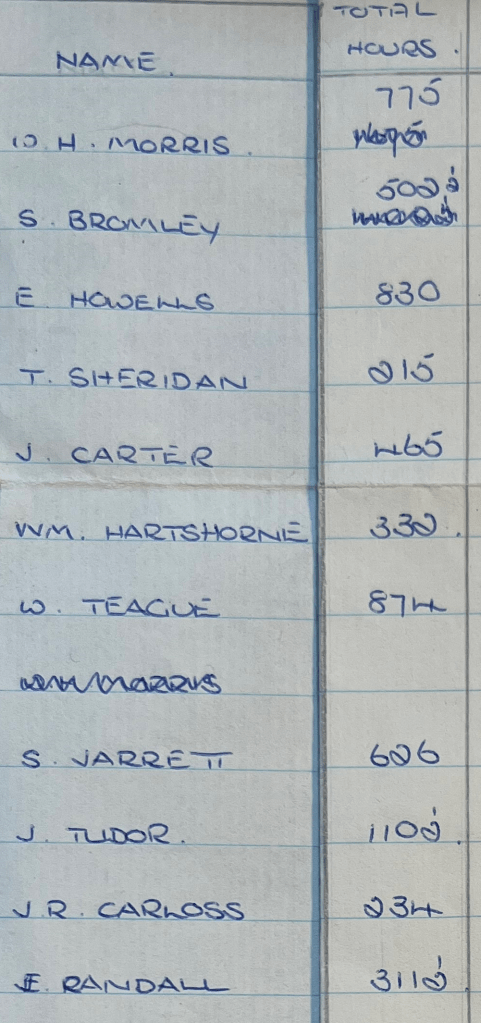

Here’s a list from Bromley’s company records of the men who worked on the bridge:

Trevor Thomas remembers being told that someone drowned in the ford, leading to more urgent calls for a bridge:

“The story goes that Downes from Upper Farm sent their waggoner to Dorrington station to get a ton of coal. It was a Saturday and it was very wet, and on the way back he stopped in the pub rather a long time. When he came to come home, it was so wet the brook was in flood, and he sat on the shaft trying to persuade the horse to go through the water. They got in the water and the horse took fright and shied and tipped the load of coal in the water. The horse managed to get free, but it sent the waggoner down into the water, and he drowned because he was pretty drunk.”

Harry Evason from Dorrington supplied the sand and gravel. It was his first ever job. Two years later (in 1927) he gave up farming and founded the company.